Concrete slabs & Flatwork

Concrete flatwork is just concrete work that is flat – perhaps more commonly termed cement pads and concrete slabs. CementWright offers all forms of flatwork, including:

- Concrete floors

- Driveways

- Steps & sidewalks or walkways

- Concrete patios

- Concrete curbing

- Garage Slabs

- Decorative concrete versions of any of the above

- Heavy structural slabs. See Industrial & Structural for those offerings.

Finishing treatments can range from broomed to coloured, stamped, exposed aggregate, or more exotic decorative options. CementWright has options for frost resistant and frost proof slabs with extended durability, and our entry level concrete work has options for long extended warranties. We offer sealed relief cuts and expansion joints against buildings. Rebar is epoxied into adjacent concrete to limit movement for maximum durability. We can offer decorative options for all our flatwork that will elevate your project from the common to the sublime. Our base level flatwork typically has 100% more gravel, 50% more rebar, and 25% more concrete than that from most of our competitors. It uses more material, so it costs a bit more, but lasts accordingly; we believe CementWright is rare in the variety, durability and craftsmanship we offer.

All portions must be done well for a concrete slab to last.

Flatwork can be done well with minimal equipment as long as the prep and finishing are done competently with good materials. This is less trivial than it sounds, especially with the frost the Albertan winter brings.

Structure of concrete slabs on grade is the sum of the concrete, rebar, and the base prep. Stinginess in any one of these can fail the slab structural envelope.

All three elements are designed and work together to carry the load placed on the concrete and to resist differential movement from frost and moisture. Concrete provides compressive strength and a hard wear surface, rebar provides tensile strength to the concrete, and the gravel base prep strengthens the soil to carry the load transmitted through the concrete slab. Grade prep and rebar placement are just as crucial to longevity as competent finishing and quality concrete. If these are done correctly and the concrete is maintained, it is possible to do concrete work that will last centuries.

sound CONCRETE NEEDS A solid BASE.

This is typically done with well compacted gravel placed on suitable compacted subgrade (clay), but there are other options such as an insulated or suspended slab on piles and void form to mitigate frost or moisture movement. Grade prep is where a lot of concrete contractors in Red Deer and area can go wrong. Leaving black dirt, silt, organics, or other deleterious materials below the gravel leaves the finished slab vulnerable to movement with the seasons and moisture, and is contrary to building code. Insufficient compaction of gravel or subgrade or meager aggregate supply creates a weak base. This can allow settling of the concrete over time, differential movement, and deterioration of the slab. Deficient base preparation can not be economically compensated for in later steps.

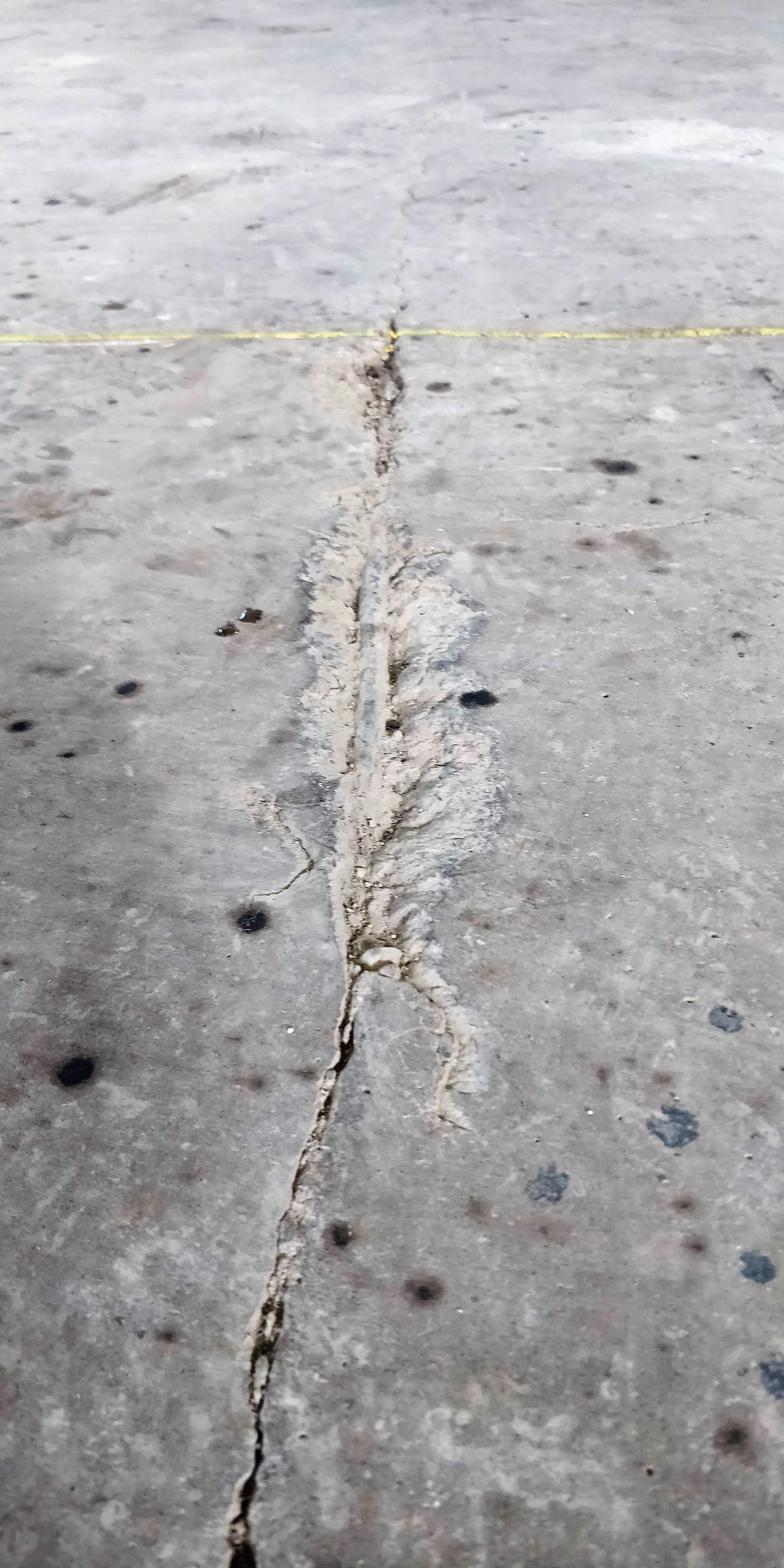

example prep & concrete failure analysis

tough CONCRETE has REINFORCEMENT

Concrete is strong in compression but weak in tension, so tensile reinforcing material, such as steel or basalt rebar, is used to provide tensile strength to concrete structures. This is a key part of concrete flatwork such as driveways and patios. Correctly sized and placed rebar distributes the load on a slab through a larger area so the concrete and subgrade can carry more. Rebar also helps control concrete cracking and shifting. For best results rebar is typically placed in the bottom 3rd of most concrete slabs. This position allows it to provide its tensile strength where it is best used, while having enough material around the bar to transfer forces into it. Most rebar related concrete failures we see come from insufficient rebar or incorrectly placed bar. Steel bar too close to a surface causes corrosion (basalt bar and fibremesh exists where this is unavoidable); bar too near the top or bottom doesn’t provide any value. ”Lifting” the bar grid during the pour is unreliable so we use rebar “chairs” to ensure correct positioning of rebar throughout the concrete placement process.

CONCRETE FINISHING & SELECTION for durability

Competently placed and cured concrete provides the wear surface and compressive strength of the slab system. Using the appropriate depth and specification of concrete is crucial to achieving a useable product. Exterior concrete should be at least 32 MPa and be air entrained to resist frost; we include fibremesh as well to toughen the surface and control shrinkage cracking. Interior concrete to receive a trowel finish should have minimal air to limit surface delamination. Concrete should not be watered down (retempered) for ease of placement. Excessive water can lead to:

- excessive shrinkage cracking during curing as the water leaves the concrete-

- strength loss through void formation and dispersion of cement particles

- frost damage and generally decreased toughness and durability.

Strong concrete pours stiff. We place our concrete using high range water reducers, or super plasticizers, to enhance workability while limiting these failure modes. Timing of the finishing operation is also integral to a durable finish; we employ an experienced crew to ensure your concrete finish lasts.

Concrete Finishing Photos

Controlling Cracks in Concrete

All our concrete includes relief cuts. They provide a clean line for the concrete to crack as it shrinks during curing, and are done with a tool during finishing or a diamond saw shortly after finishing is complete. Correct relief cuts require understanding of how stress flows through concrete in order to place them correctly. Timing of these is really important- if cuts are done too late, the concrete will already have shrunk and cracked, so though the effects won’t yet be visible, the cuts don’t help much. Late cuts are wasted cuts. We self perform our own cutting to ensure cuts are positioned correctly and done in time.

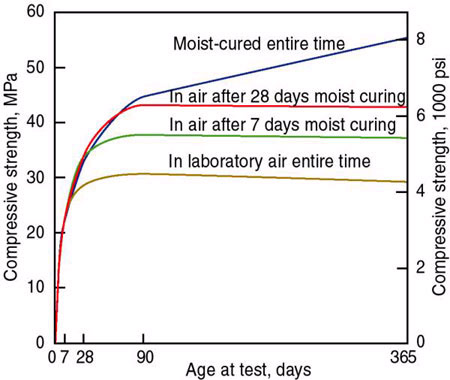

Curing concrete for maximum strength

Properly curing concrete is also often overlooked in flatwork. This is unfortunate, because correctly cured concrete can provide substantially more strength compared with air cured concrete without much cost. Curing is done by ensuring sufficient water is available to keep the cement hydration reaction going. We typically use a membrane curing compound directly after finishing, but have done water cures as well depending on the application.

Maintenance of Concrete

Exterior concrete should be maintained with regular cleaning and sealing to prevent stains and to control deterioration from salt and other compounds. Maintenance of concrete applies mostly to exterior work, though interior concrete can benefit from regular care. See our concrete sealing and repair page for more details. If you have come into possession of concrete that has deteriorated, we still may be able to help mitigate the damage and prevent future problems.

CementWright offers a lot of flatwork concrete services to Red Deer and area. We provide solutions that set the standard for service and reliability. We’re willing to educate you on options available for your concrete project. Contact us and we’ll chat.